Product Reviews

Pew Pew Tactical | M1 Carbine (Auto Ordnance): Blast From the Past Review.

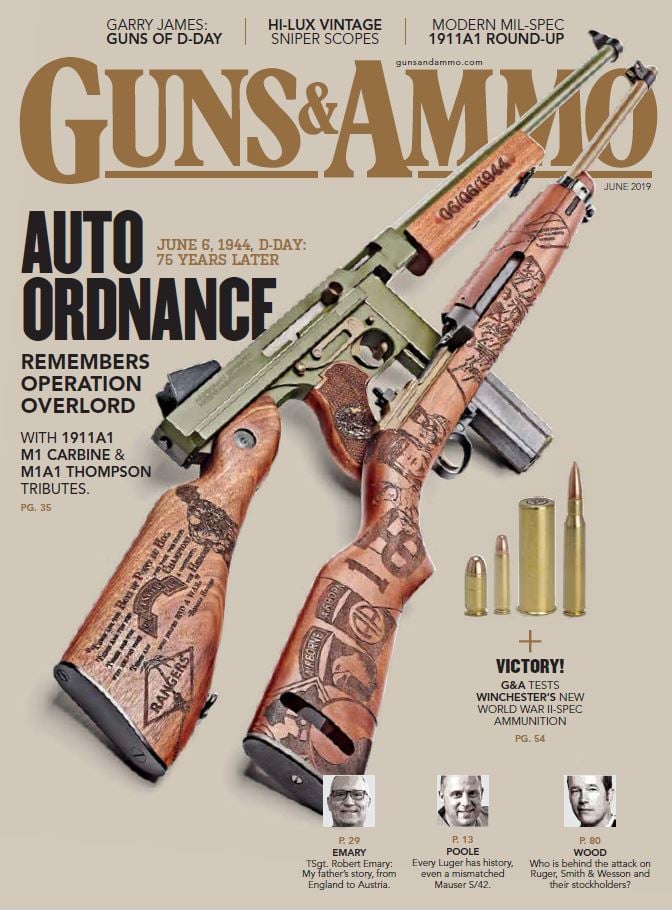

The M1 Garand tends to get most of the American WWII glory, but it’s not the only cool firearm from the ’40s! If you’re looking

The M1 Garand tends to get most of the American WWII glory, but it’s not the only cool firearm from the ’40s! If you’re looking

Date: August 19, 2019Author: Frank Melloni In early 2019, Auto-Ordnance released a commemorative pistol to honor our current Commander in Chief, Donald J. Trump. As he is

Click here to read the article.

Author: JEFF “TANK” HOOVER The 1911 is the most recognized and highly respected pistol to most mere mortals. Successfully serving our military for 75 years, it

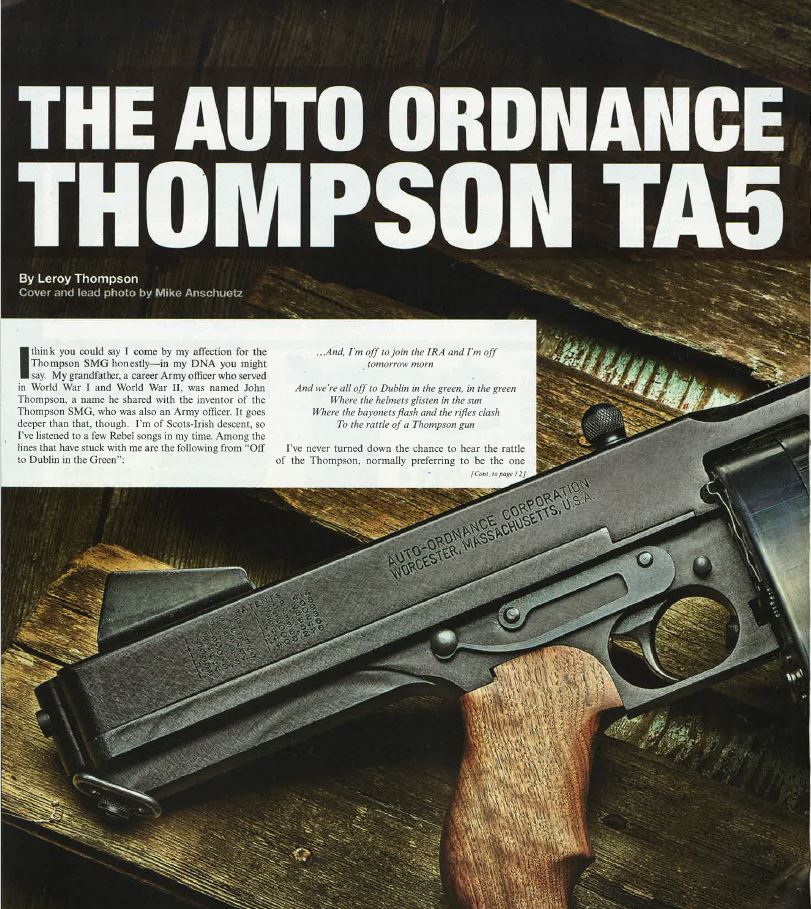

Author: Leroy Thompson Click here to read the article.

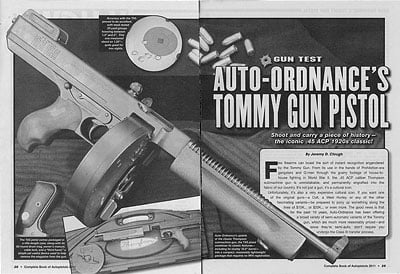

Shoot and carry a piece of history—the iconic .45 ACP 1920s classic! The Complete Book of Autopistols 2011, page 28 ~ 33 By Jeremy D. Clough